Camera Module OEM & ODM

one-stop service from design to manufacturing!

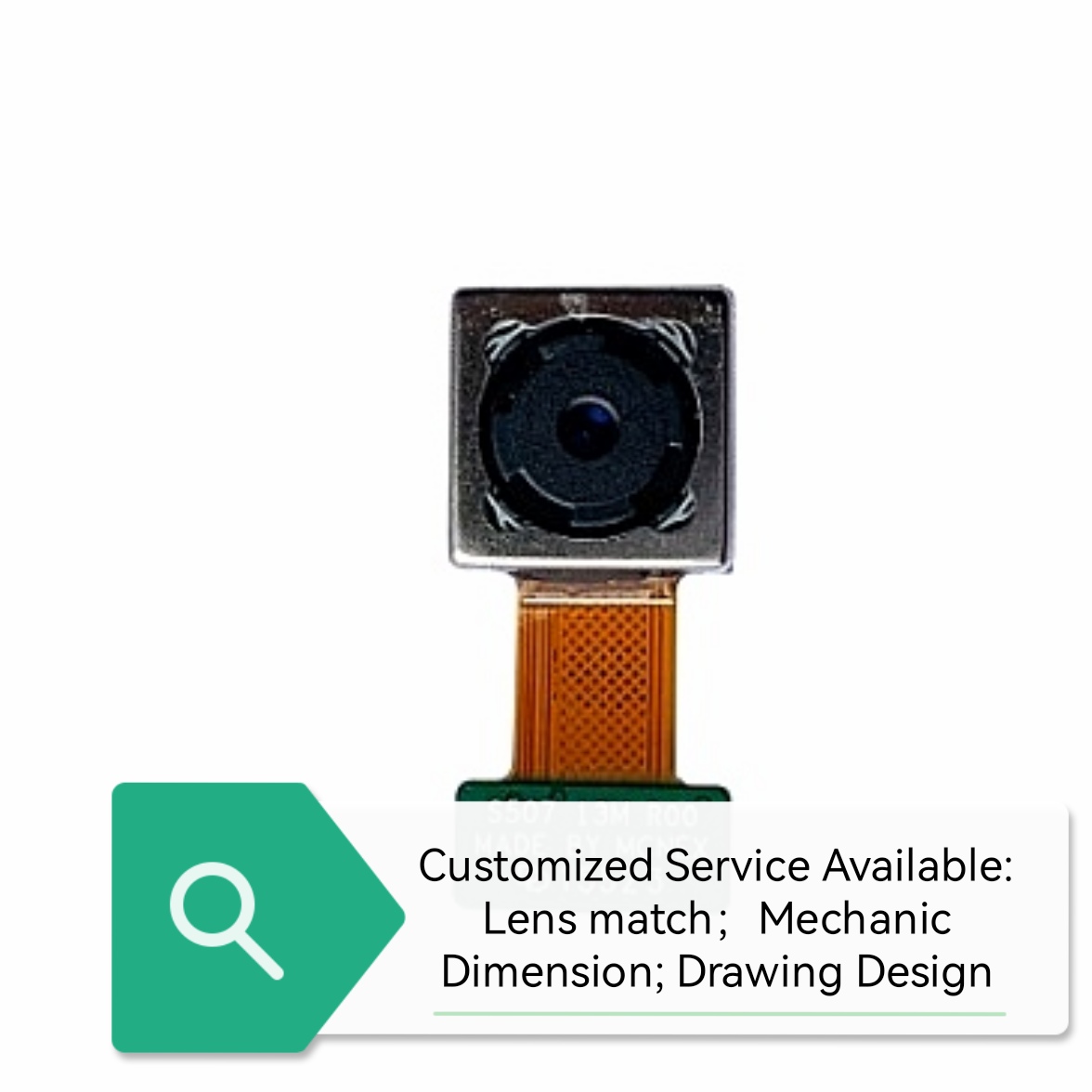

Camera modules could be embedded in various mobile devices to capture photos and videos, such as smartphones, smart home appliances, and smart scanning products.

In all fields, a high level of technology is required, requiring high resolution, and low power consumption. Our well-trained R&D team would provide satisfying camera modules pro type and great support according to your application, from design to manufacturing, we offer a one-stop service so u could focus on what you are good at.

Custom solutions according to your camera module resolution request (up to 13M resolution):

| Wide Selection of Camera Sensors | |||||

| Resolution | Brand | Sensor | Size | Format Supportable | Frame Frequency |

| 16M | SONY | IMX298 | 1/2.8 | YUY2/MJPG | 10fps |

| 13M | SONY | IMX258 | 1/3.06 | YUY2/MJPG | 15fps |

| 10M | Onsemi | MT9J003 | 1/2.3 | YUY2/MJPG | 15fps |

| 4K | OmniVision | OSO8A10 | 1/1.8 | YUY2/MJPG | 30fps |

| 4K | SONY | IMX415 | 1/2.8 | YUY2/MJPG | 30fps |

| 4K | SONY | IMX317 | 1/2.5 | YUY2/MJPG | 30fps |

| 4K | SONY | IMX179 | 1/3.2 | YUY2/MJPG | 30fps |

| 4K | SONY | IMX219 | 1/4 | YUY2/MJPG | 15fps |

| 5M | OmniVision | OV5640 | 1/4 | YUY2/MJPG | 15fps |

| 5M | Onsemi | AR0521 | 1/2.5 | YUY2/MJPG | 25fps |

| 5M | PixArt | PS5520 | 1/2.5 | YUY2/MJPG | 30fps |

| 5M | OmniVision | OV5693 | 1/4 | YUY2/MJPG | 30fps |

| 5M | Galaxycore | GC5035 | 1/5 | YUY2/MJPG | 30fps |

| 5M | OmniVision | OV4689 | 1/3 | YUY2/MJPG | 30fps |

| 3M | Galaxycore | GC4653 | 1/3 | YUY2/MJPG | 30fps |

| 3M | Onsemi | AR0331 | 1/3 | YUY2/MJPG | 25fps |

| 3M | Onsemi | AR0330 | 1/3 | YUY2/MJPG | 30fps |

| 2M | SONY | IMX385 | 1/1.8 | YUY2/MJPG | 30fps |

| 2M | Galaxycore | GC2053 | 1/2.9 | YUY2/MJPG | 30fps |

| 2M | Galaxycore | GC2145 | 1/4 | YUY2/MJPG | 20fps |

| 2M | SONY | IMX307 | 1/2.8 | YUY2/MJPG | 30fps |

| 2M | SONY | IMX323 | 1/2.9 | YUY2/MJPG | 30fps |

| 2M | OmniVision | OV2740 | 1/4 | YUY2/MJPG | 30fps |

| 2M | OmniVision | OV3660 | 1/5 | YUY2/MJPG/ H.264 | 20fps |

| 2M | OmniVision | OV2710 | 1/2.7 | YUY2/MJPG/ H.264 | 30fps |

| 2M | Himax | HM2131 | 1/2.7 | YUY2/MJPG | 30fps |

| 2M | SONY | IMX291 | 1/2.8 | YUY2/MJPG/ H.264 | 30fps |

| 1.3M | Onsemi | AR0130 | 1/3 | YUY2/MJPG/H.264 | 30fps |

| 1.3M | OmniVision | OV9281 | 1/4 | YUY2/MJPG | 30fps |

| 1M | Onsemi | AR0135 | 1/4 | YUY2/MJPG | 30fps |

| 1M | Galaxycore | GC1064 | 1/3.6 | YUY2/MJPG/H.264 | 30fps |

| 1M | OmniVision | OV9732 | 1/4 | YUY2/MJPG/H.264 | 30fps |

| 1M | SONY | IMX225 | 1/3 | YUY2/MJPG/H.264 | 30fps |

| 1M | Himax | HM1091 | 1/9 | YUY2/MJPG | 30fps |

| VGA | Galaxycore | GC0308 | 1/6.5 | YUY2 | 30fps |

| VGA | OmniVision | OV2659 | 1/5 | YUY2 | 30fps |

| VGA | OmniVision | OV7740 | 1/5 | anolog | 30fps |

| VGA | OmniVision | OV7251 | 1/7.5 | YUY2/MJPG | 30fps |

| VGA | OmniVision | OV7725 | 1/4 | YUY2 | 30fps |

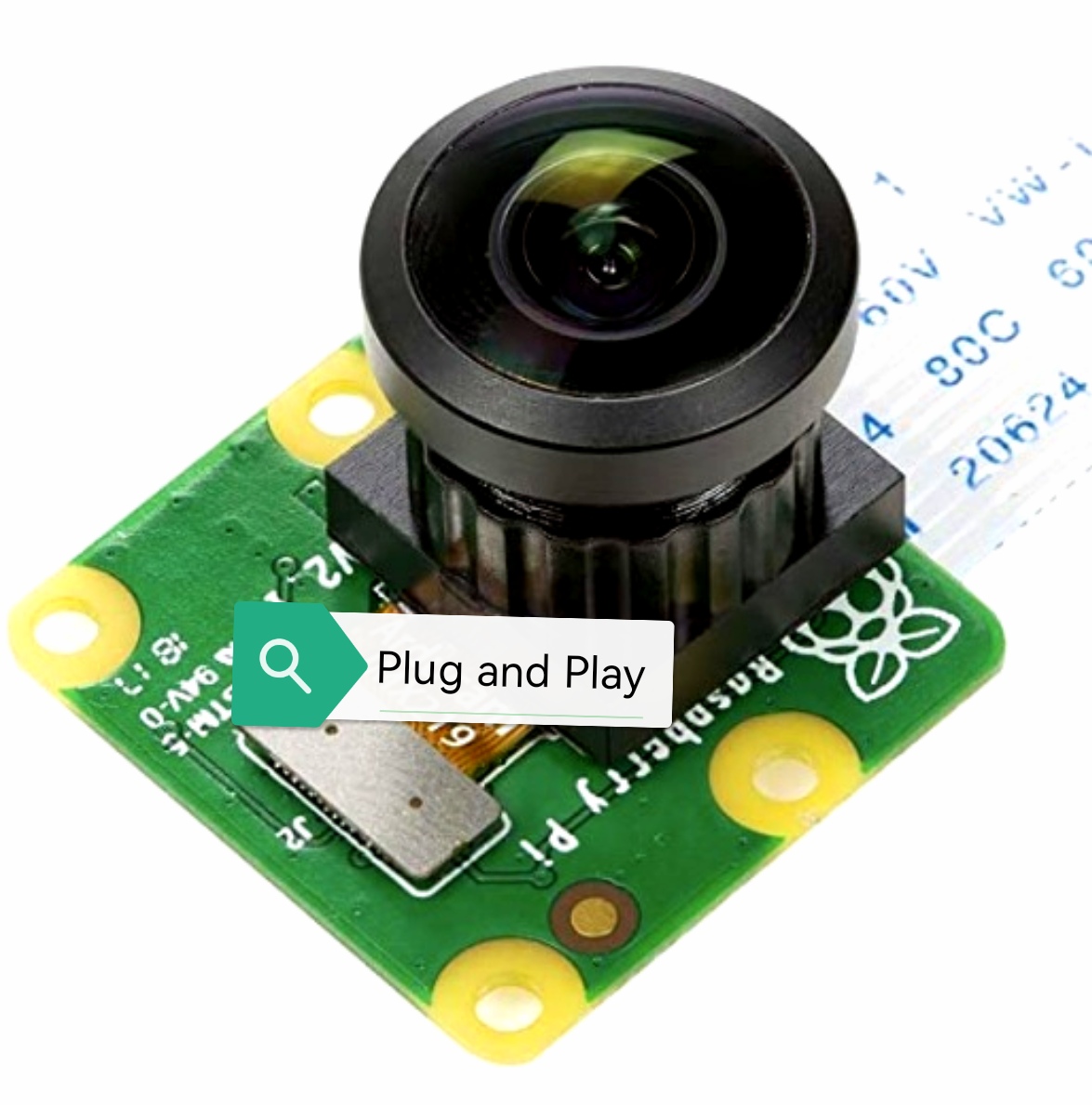

Lenses / custom filter/FoV options

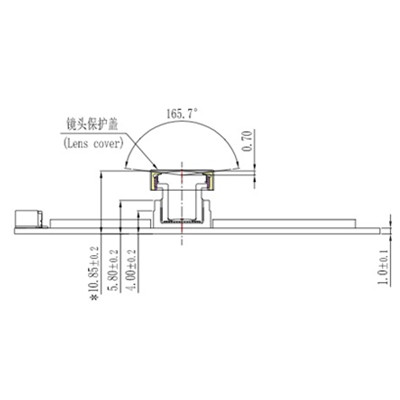

From the field of view, it could be divided into ordinary lenses (about 50 degrees to 70 degrees), wide-angle lenses, ultra-wide-angle lenses and fisheye lenses.

The field of view of the wide-angle lens is generally around 80°, which is mainly used for shooting general scenes. The ultra-wide-angle lens is used for shooting scenes such as landscapes, buildings, and group photos. The fisheye lens is an extreme wide-angle lens and the view angle even reaches 180°, the diameter of the lens is very short and protrudes outward, similar to the eyes of fish, and is widely used in the fields of scene monitoring, robot navigation and measurement.

According to your FOV request, flexibly match the most suitable lens, a wide selection of view angles such as :

| Diagonal (°) | Vertical (°) | Horizontal (°) |

| 180 | 180 | 180 |

| 170 | 161.1 | 166 |

| 120.0 | 90 | 111.1 |

| 115.2 | 81.2 | 102 |

| 107.1 | 73.9 | 95.1 |

| 90.5 | 61.9 | 82.4 |

| 80.1 | 53.1 | 73.7 |

| 63.4 | 37.8 | 54.4 |

| 46.8 | 27 | 39.6 |

| 34.4 | 19.5 | 28.8 |

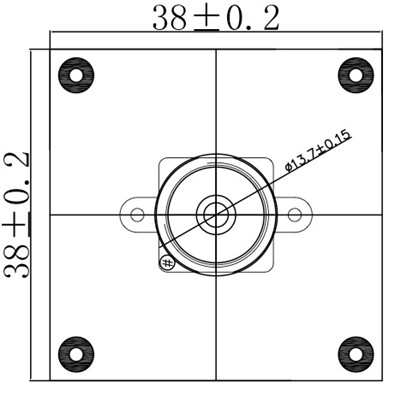

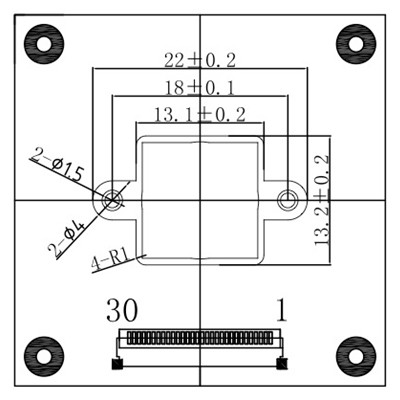

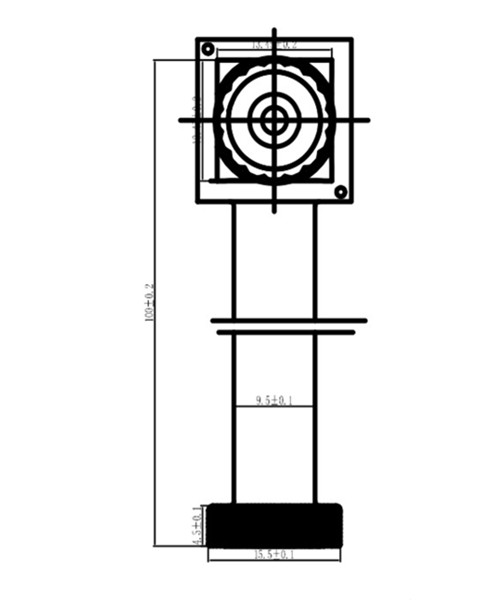

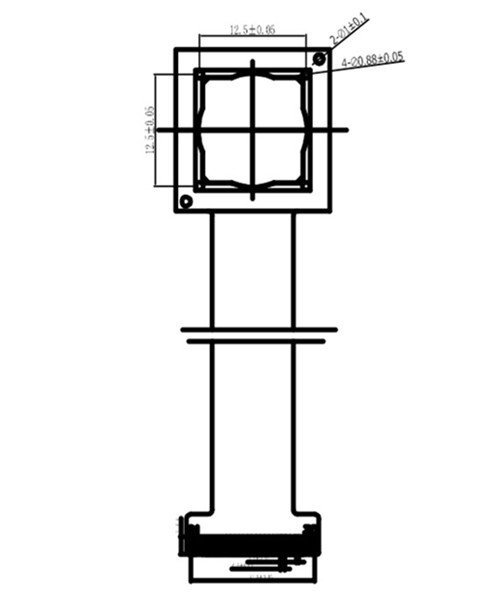

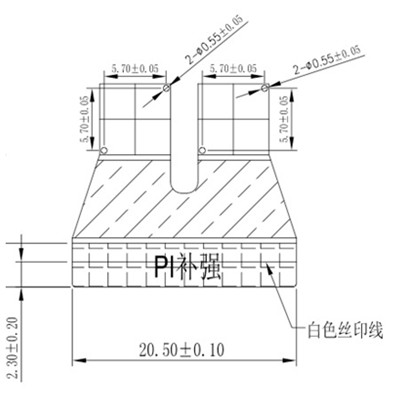

Custom module shape

The mechanical size of the module can be designed according to the assembly requirements.

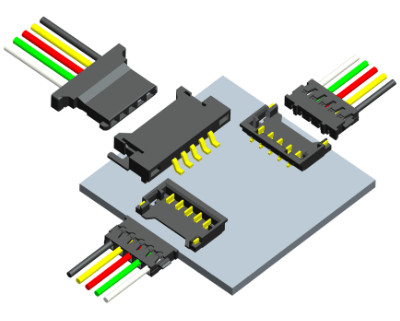

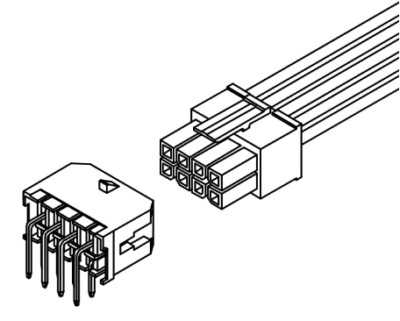

Custom connector types

Camera interface flexible selection:

In short, you only need to tell us the following points, and let us do the rest:

1. Your application of the required camera module

2. Your required resolution of the camera module

3. Your Preferred field of view of the camera module

4. Your required interface for the camera module

5. Your requirements on the dimensions of the camera module if any

6. Your expected image format (RAW, MJPEG, YUV, etc.)

7. Your backend processor if possible

Our experienced team of engineers will design a camera module prototype suitable for your application based on the requirements you provide, and further discuss with you to improve product details until mass production.

If u have modules currently in use for prototype (pictures/ links/), that will promote the development and just feel free to discuss with us.

Contact us now to make your idea into reality!

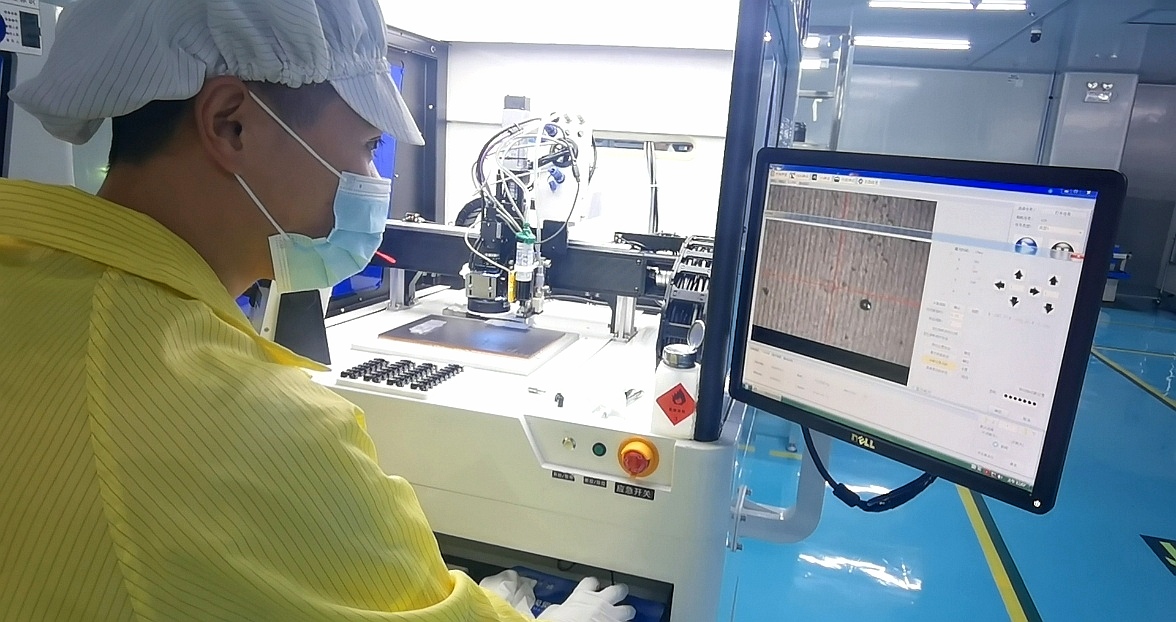

Camera Module Manufacturing

| IQC | Inspection Contents | Inspection system/equipments used |

| RFPC/FPC inspection | Length/width/thickness | caliper |

| positioning hole | Three-dimensional measuring instrument | |

| PP overflow glue | microscope | |

| Coating thickness | Film Thickness Tester | |

| Steel sheet/reinforcing plate resistance | ||

| Welding bubbles | multimeter | |

| Thrust tester (original thrust) | X-Rry | |

| slice | Push-pull machine | |

| Bend test | ||

| Solderability | Three-dimensional measuring instrument | |

| Flatness test |

Bending testing machine |

|

| Visual inspection | ||

| Product production date and expiration date | ||

| Lens inspection | size | Tin stove |

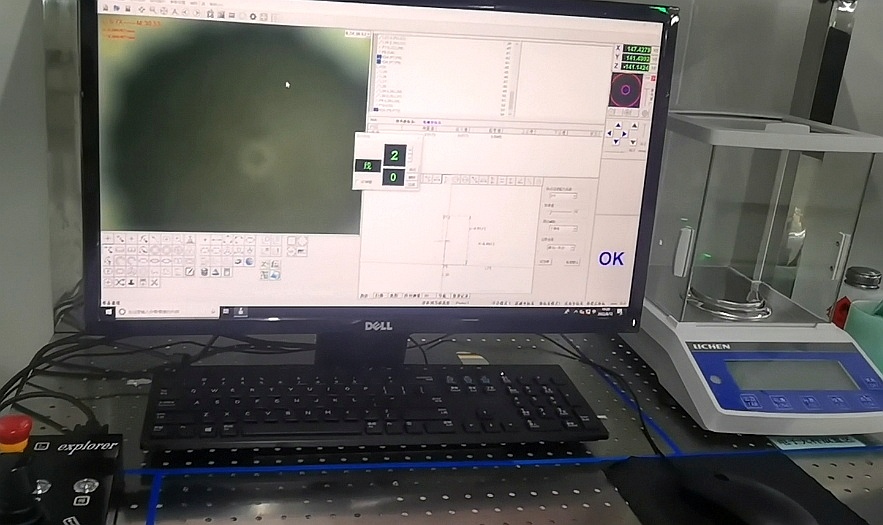

| Lens resolution | OGP | |

| Visual inspection | microscope | |

|

IR+Holder subassembly |

Critical dimensions (as defined by drawings, increase/decrease monitoring items) | |

| IR and holder edge fit gap | Calipers, three-dimensional measuring tools" | |

| IR cut surface | Three-dimensional measurement tool | |

| IR transmittance | microscope | |

| IR Adhesion | Spectrometer | |

| IR film adhesion | Push-pull machine | |

| Visual inspection | 3M | |

| Holder inspection | size | microscope |

| Visual inspection | caliper | |

| Protective Film inspection | viscosity | microscope |

| Visual inspection | microscope | |

| ESD test | microscope | |

| Incoming inspection of capacitors, resistors, ICs and other electronic materials | Solderability | "Tin stove |

| Capacitance resistance | microscope" | |

| Capacitance | three-dimensional | |

| Resistance | bridge | |

| Visual inspection | bridge | |

| Tray incoming inspection | critical dimension | microscope |

| ESD test | caliper | |

| Solder paste incoming inspection | Solder paste brand/model | Surface Impedance Tester |

| Insulation Resistance Test | Label | |

| Flux content | Impedance Tester | |

| Viscosity | Content tester | |

| Incoming tin wire inspection | Tin wire brand/model | Viscometer |

| Flux content | Impedance Tester | |

| Insulation Resistance Test | Content tester | |

| Incoming material inspection | glue | Viscometer |

| Gold Line | marking |

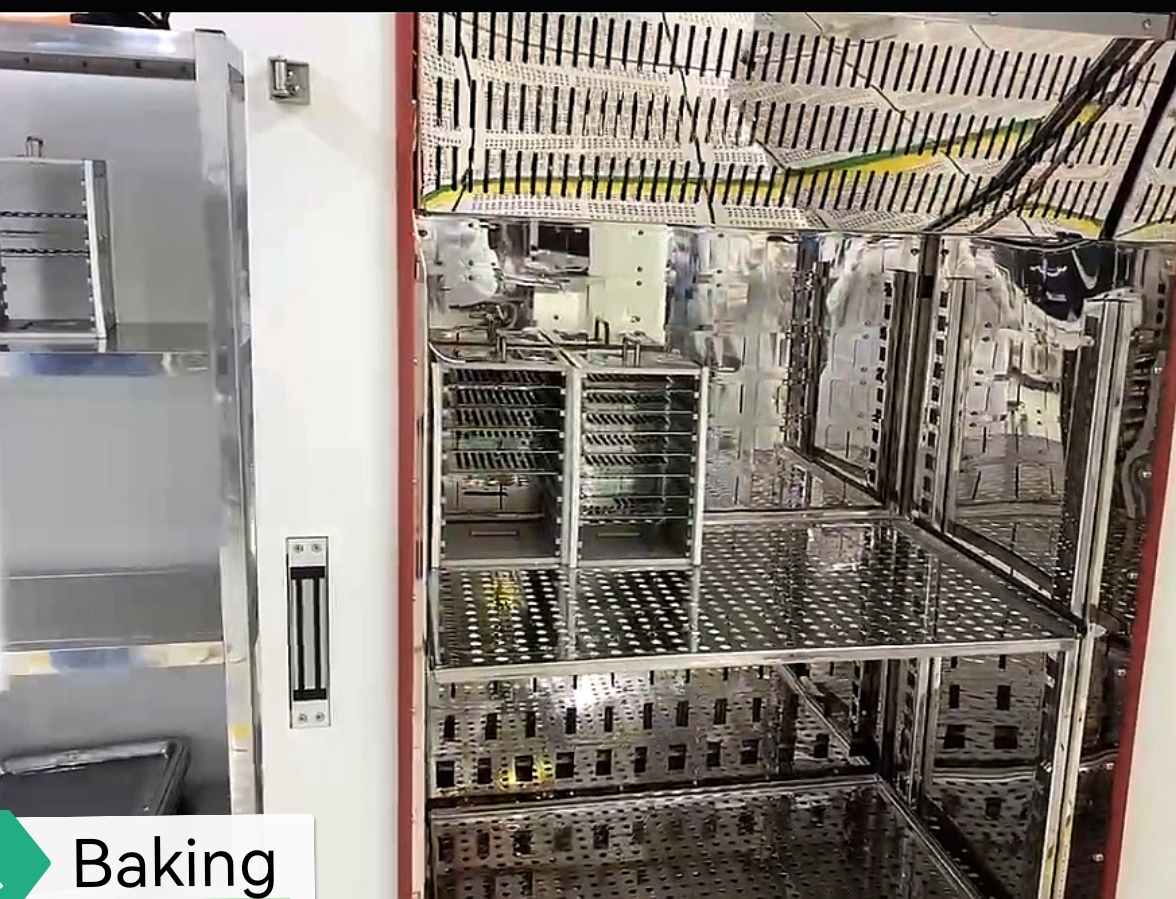

SMT Quality Control

| NO. | Process | Content | Process Specifications/Errors | Feature level (CTQ key station "▲", regular station "★") |

| 1 | bake | Baking temperature | 150℃ | ★ |

| bake time | 2H | |||

| Oven spot inspection control method | Monitor the 5-point test | |||

| 2 | Exterior | Aging after FPC baking | 12H | |

| FPC stack height | ≤10cm | |||

| 3 | FPC mount | Appearance | After the product returns to room temperature, there is no abnormal phenomenon such as discoloration, deformation, etc. | ★ |

| Illumination | 600-800 | |||

| Fixture flatness | 0.2mm | |||

| Exterior | The substrate sticking fixture is flat; the high temperature glue cannot be attached to the FPC pad or gold finger; the FPC cannot be stacked after it is mounted. | |||

| Appearance | ||||

| 4 | Solder Paste Printing | Steel mesh use environment | Equipment automatic cleaning; 1 time / each piece; less than 3 pieces | ★ |

| Manual cleaning: 1 time; less than 20 pieces | ||||

| Stencil Cleaning Equipment | Steel mesh automatic cleaning equipment | |||

| Tension Standard Test |

Five points of tension (four corners, middle) 30 | |||

| 5-point tension difference of steel mesh | ≤11N/CM | |||

| Stencil Specifications | 1.0mm | |||

| Steel mesh usage times | 100000 | |||

| Solder paste usage environment | Temperature: 22~27℃ Humidity: 45%~60 | |||

| Warming time | 2H | |||

| Open expiration date | 24H | |||

| Stiring time | 3min | |||

| Viscosity | Set according to the specific solder paste type | ★ | ||

| Validity period | Solder paste validity period: 6 months | |||

| Scraper speed | 60±20mm/sec. | |||

| Squeegee pressure | 3~5Kg/Cm2 | |||

| Scraper life | 100,000 times | |||

| scraper angle | 45~60° | |||

| Scraper flatness | Placed on a marble platform, one side is illuminated with light, and the other end is free of light leakage | |||

| Printing effect check | No tin, less tin, missing printing, thin tin, thick tin and other undesirable phenomena; BGA pads are full | |||

| Open expiration date | 100,000 times | |||

| 5 | ★SPI | Solder paste thickness | 60-150% | ▲ |

| CPK control>1.33 | CPK control>1.33 | |||

| Solder paste volume | 50--180% | |||

| solder paste area | 60--180% | |||

| 6 | SMT | pressure | Depending on the component height, no overvoltage can occur. Air pressure: 0.4~0.6Mpa; | ★ |

| speed | 100 | |||

| angle | 90 | |||

| Loading, changing | No wrong material. Wrong direction of components, etc. | |||

| capacitance | Measured according to BOM specifications | |||

| chip | By BOM model | |||

| resistance | Measured according to BOM specifications | |||

| 7 | Previous furnace inspection | Exterior |

"1. Are there any defects such as leakage, drop, wrong, reverse, offset, damage, etc. of the mounted components? 2. The pads on the FPC/PCB board have no defects such as excessive tin, less tin, and offset of printed solder paste" |

★ |

| 8 | Furnace control | conveyor belt speed | Recommend 650~750; do DOE verification; | ★ |

| Heating slope | 40-170℃(1-3)℃/s | |||

| constant temperature | 150-180℃(60-120s) | |||

| peak | 235-250℃ | |||

| cooling zone | 250-170℃(-3.99-0.99)℃/s | |||

| 9 | After Furnace Inspection | Exterior | There are no adverse phenomena such as reverse, less tin, more tin, virtual welding, short circuit, reverse sticking, few pieces, many pieces, wrong pieces, and tombstones | ★ |

| Solder joint INC thickness | Slicing required: 1~3um | |||

| X-ray sampling ratio | ≥20% No bubbles | |||

| capacitance | 0201≥0.8Kg, 0402≥1.00Kg, 0603≥1.2Kg, 0805≥1.5Kg | |||

| IC | The standard for components smaller than 8mm is ≥1.8Kg, the standard for components larger than 8mm and smaller than 25mm is ≥2.0Kg, and the standard for components larger than 25mm is ≥3.00Kg | |||

| Connector | ≥2.2KG |

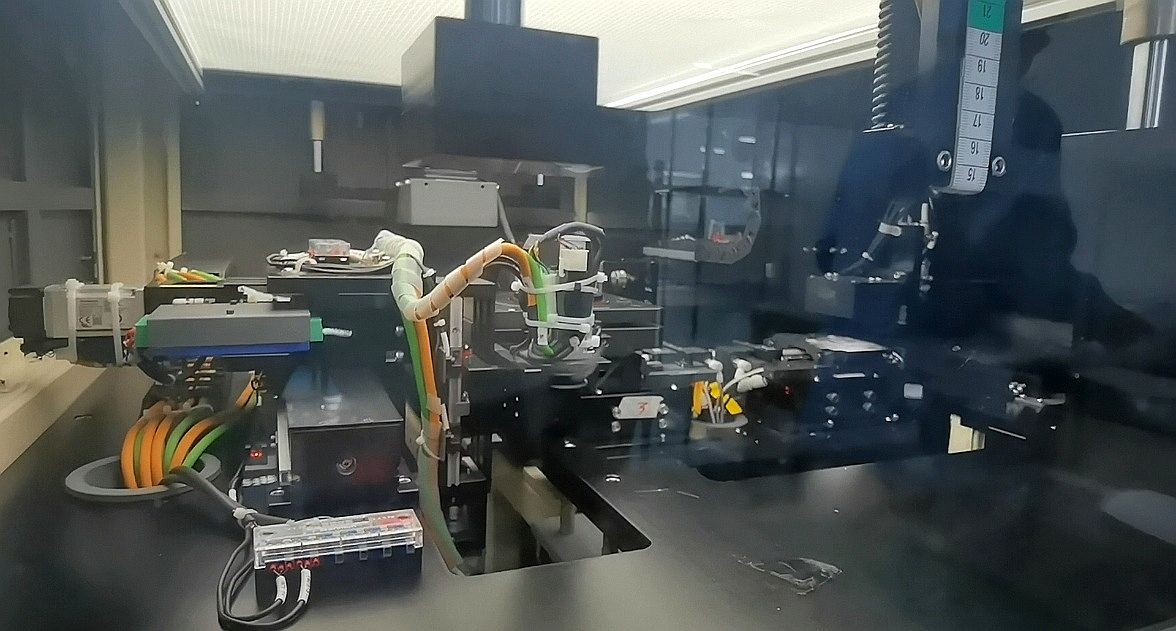

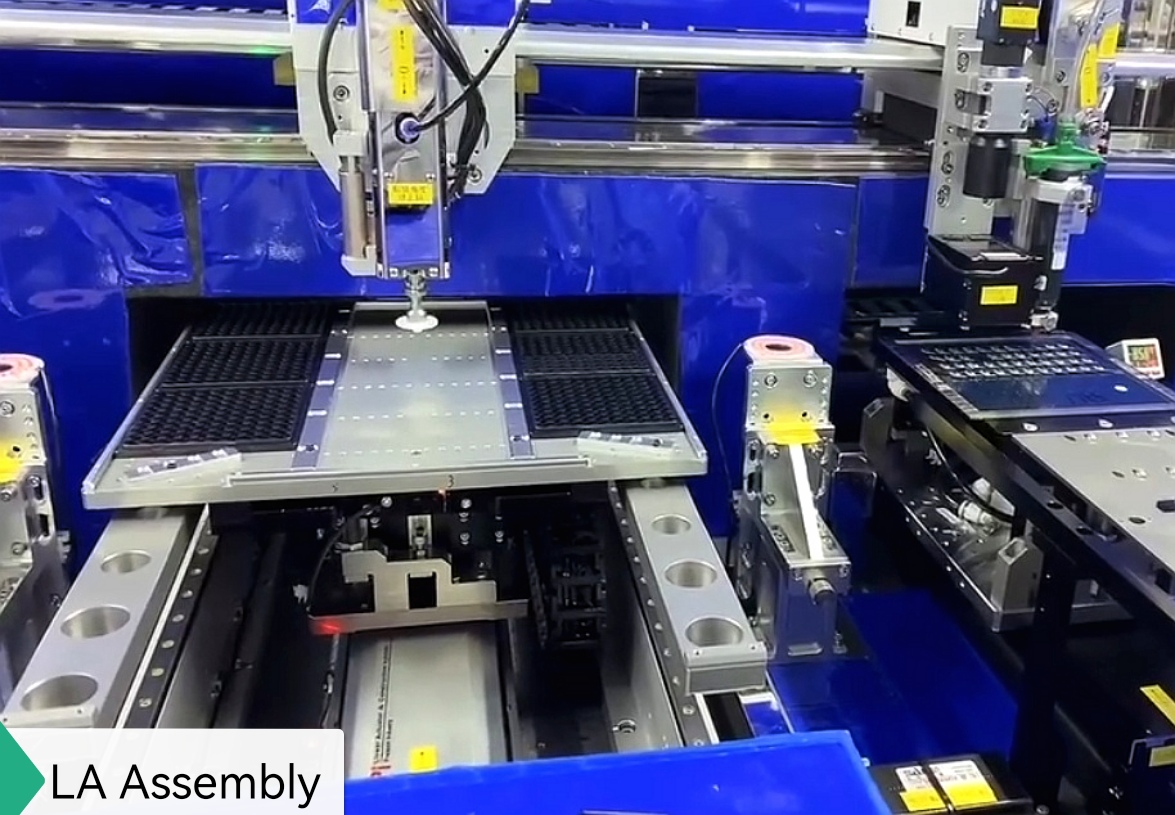

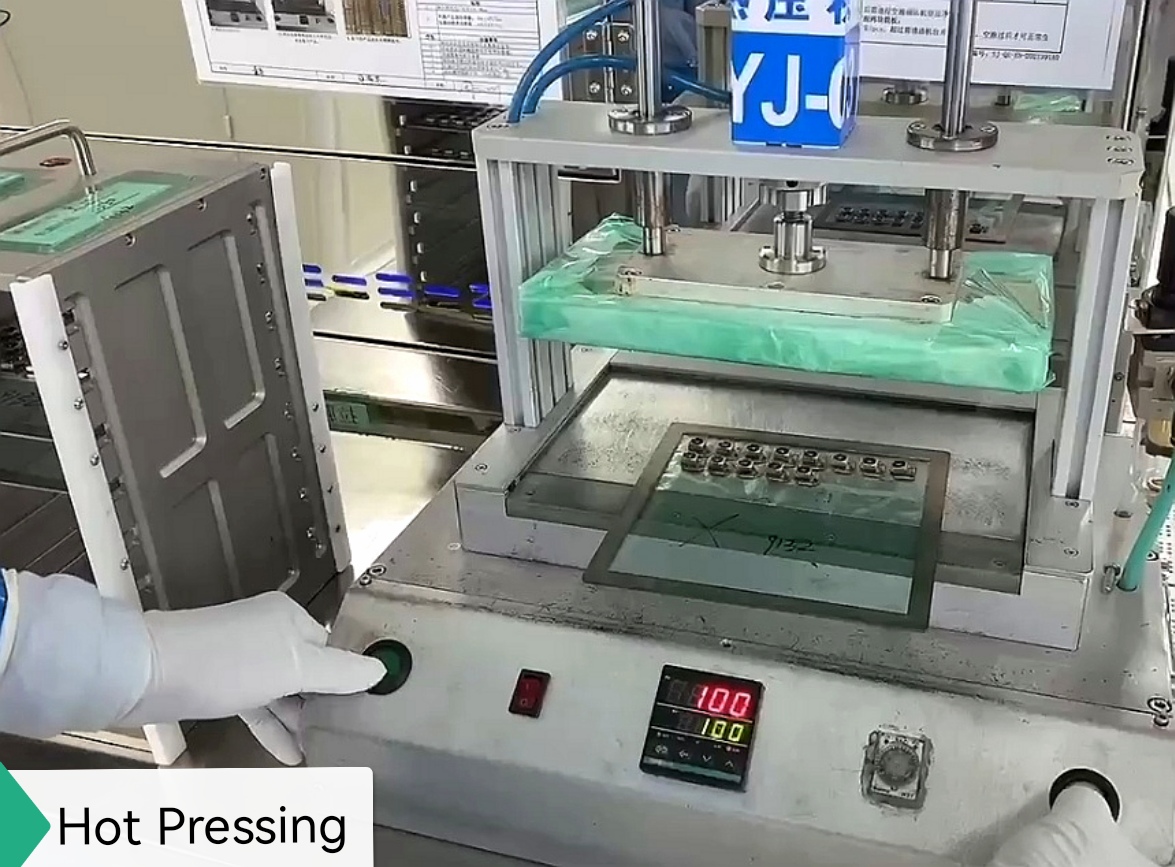

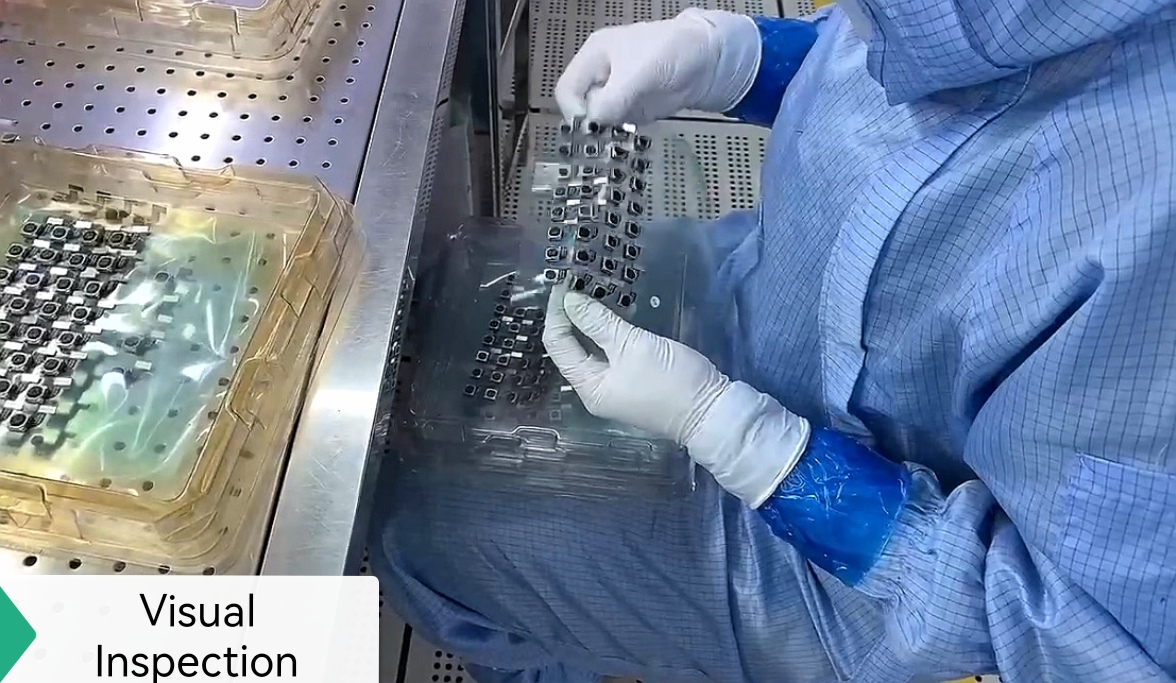

FOL ( Front of Lineup ) Craft Processes

Ultrasonic Cleaning - Chip Cleaning - LA Assembly - Hot Pressing - Baking - Visual Inspection

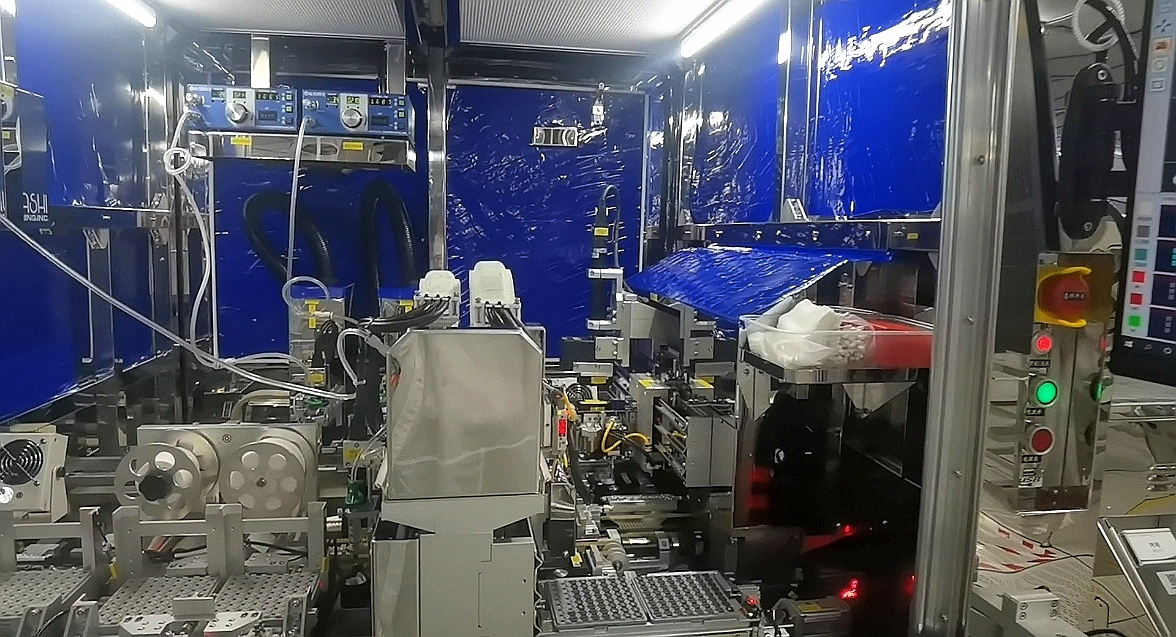

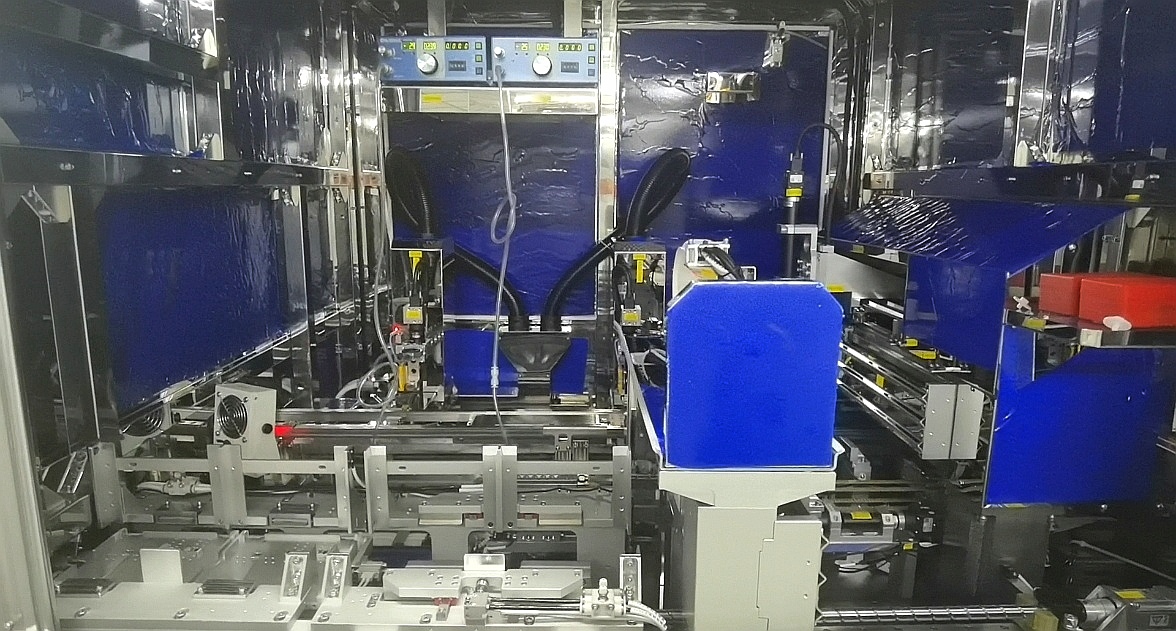

EOL( End of Lineup ) Craft Processes

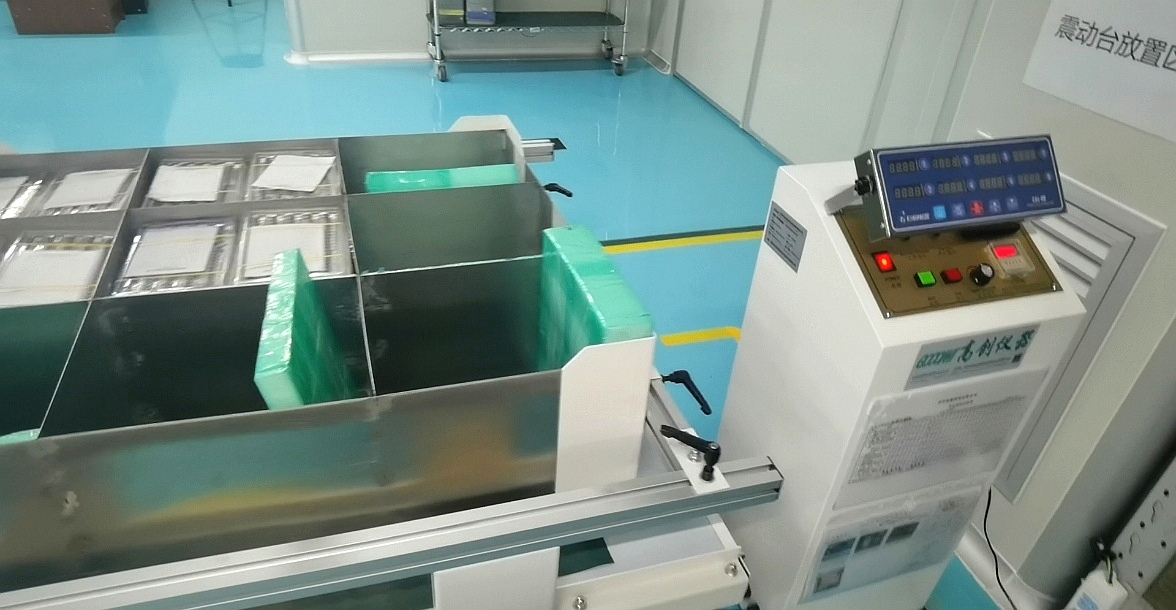

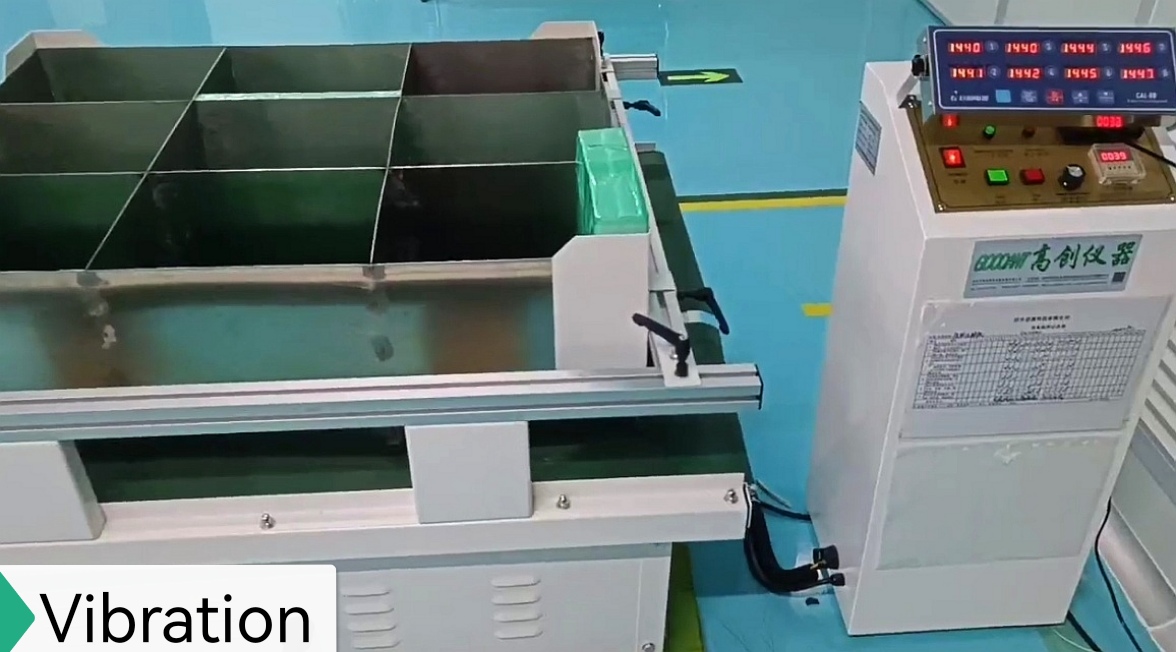

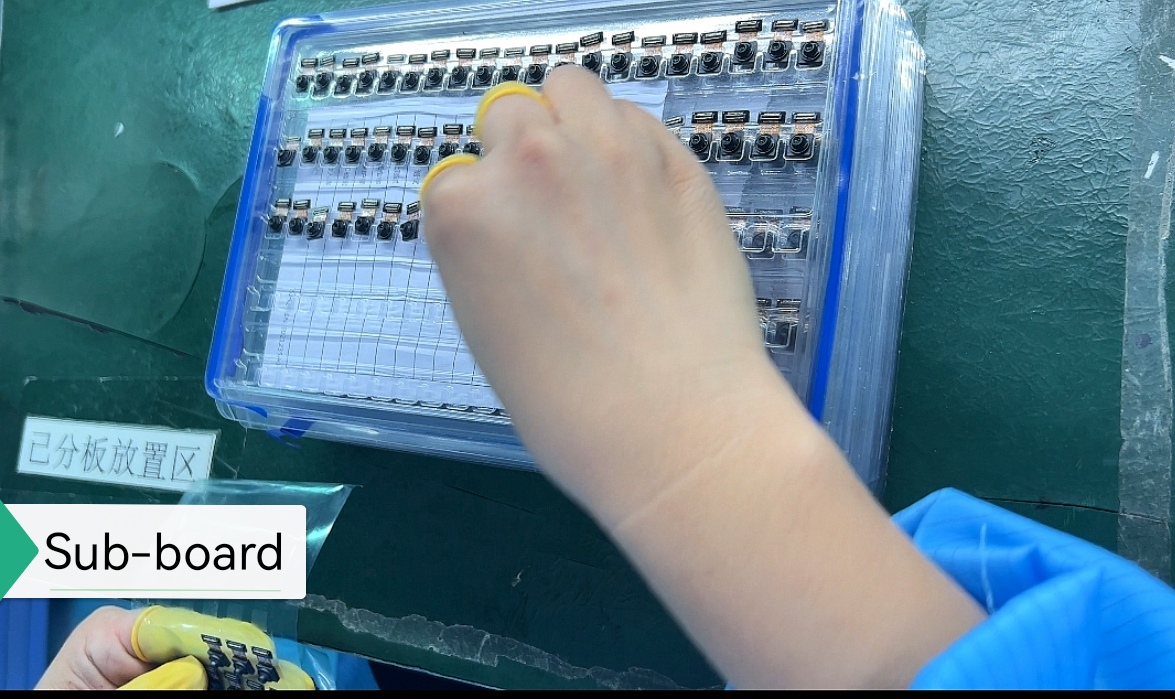

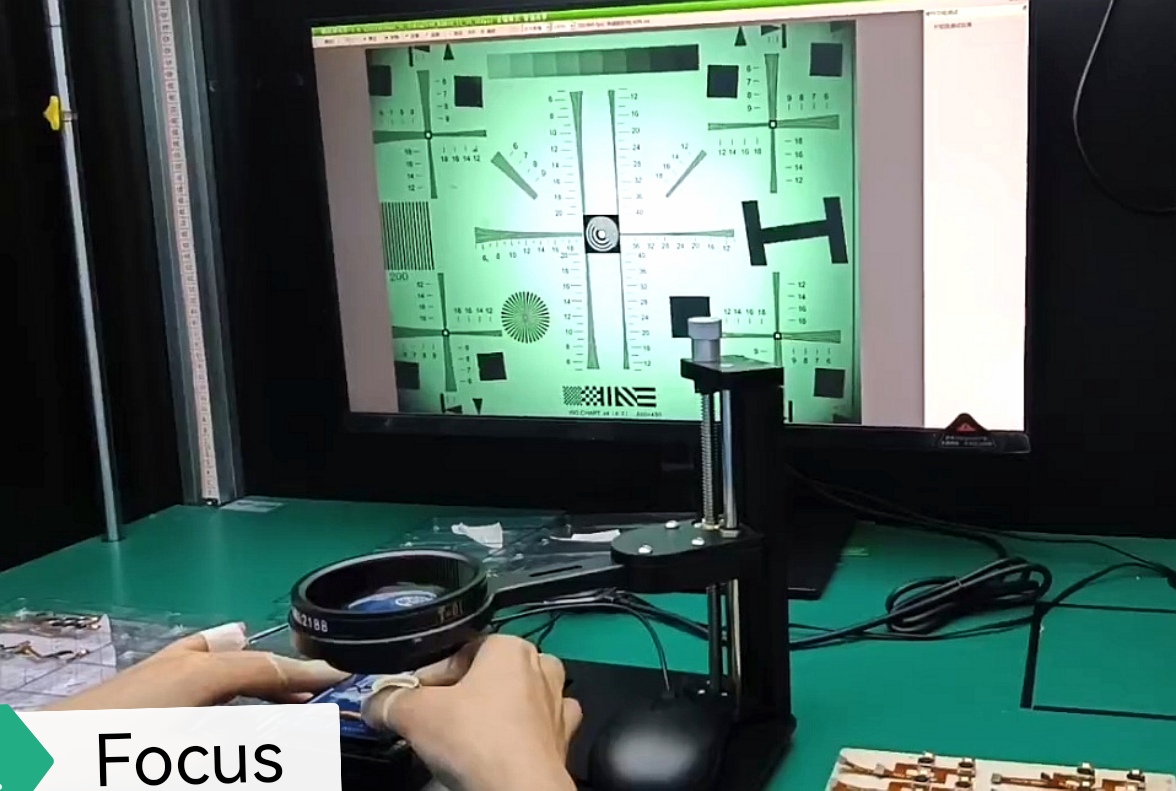

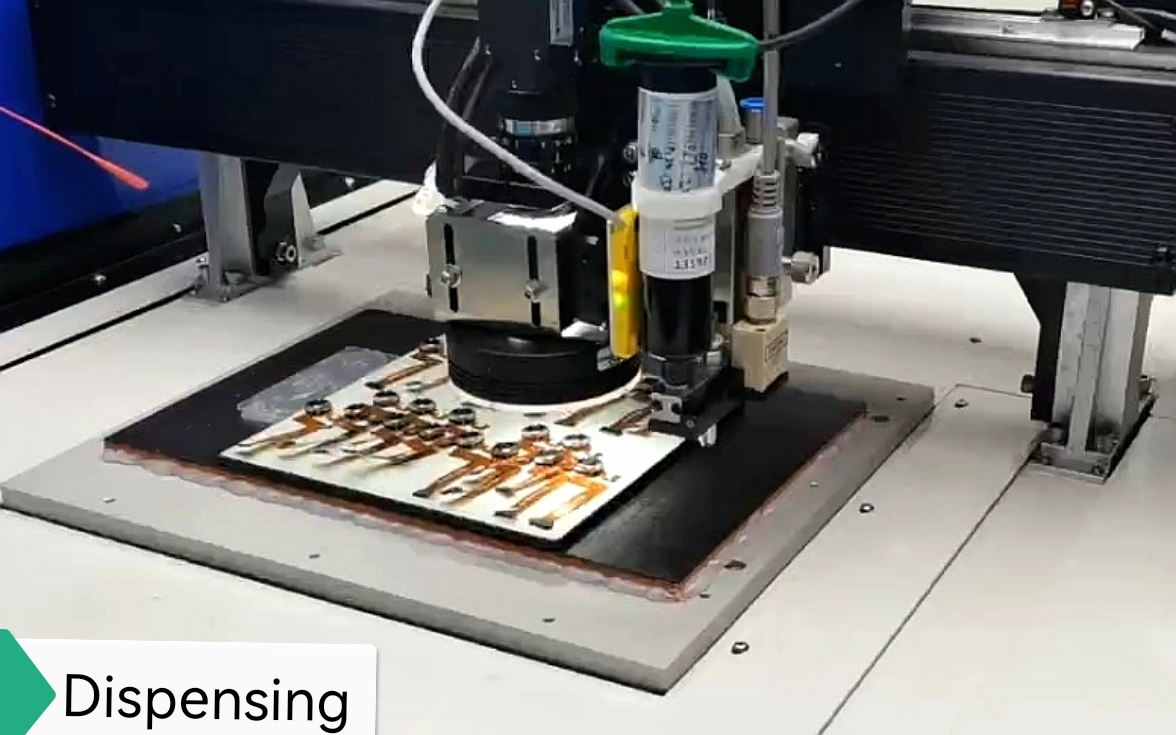

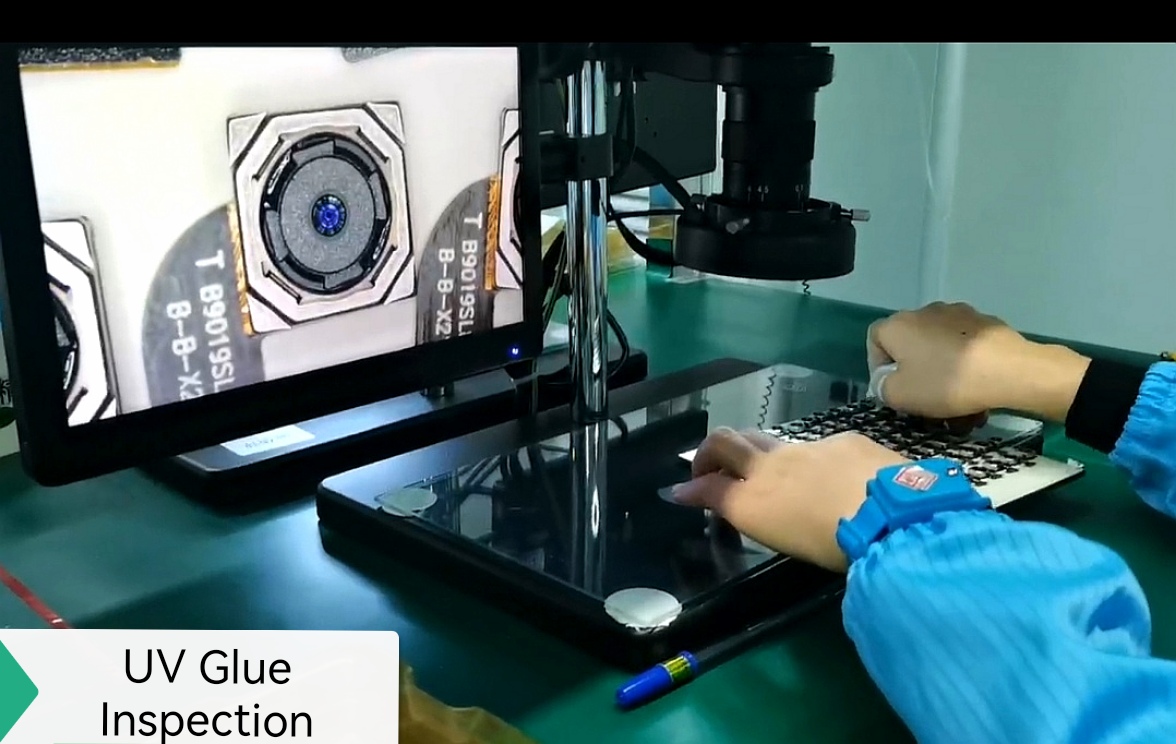

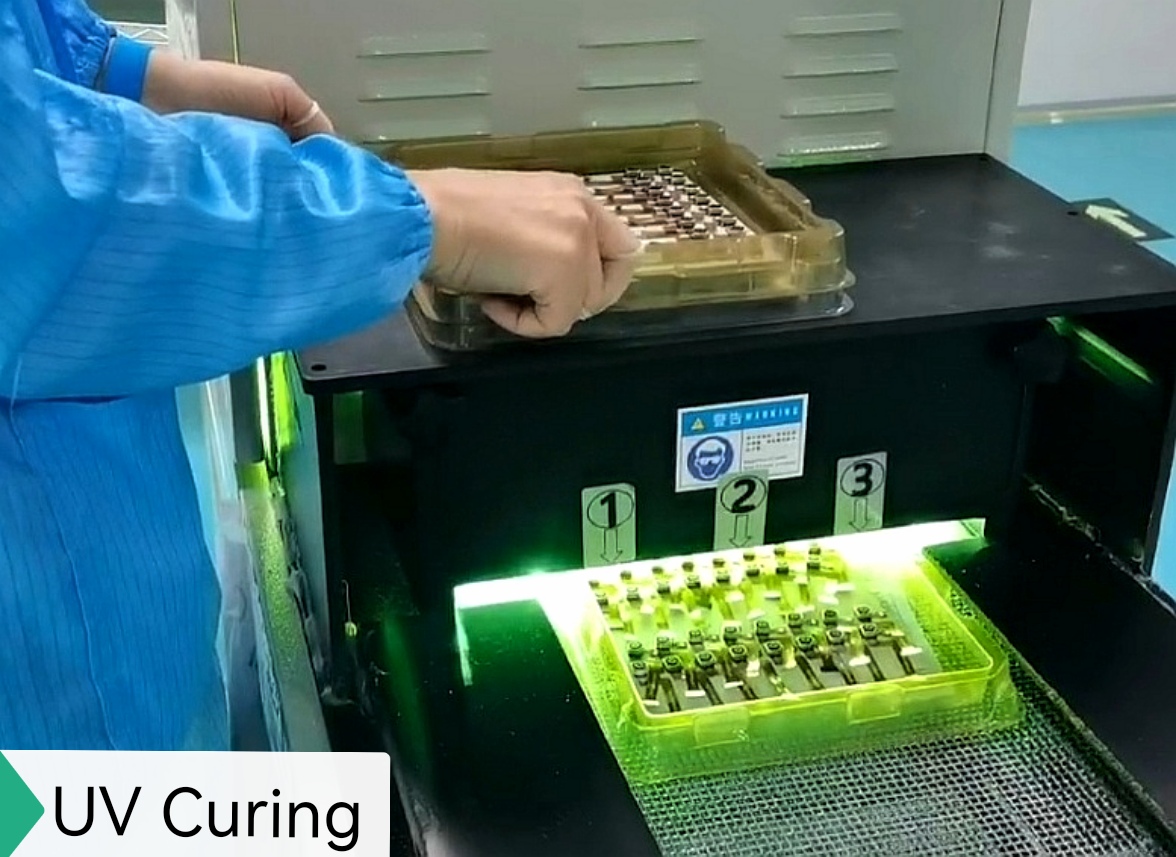

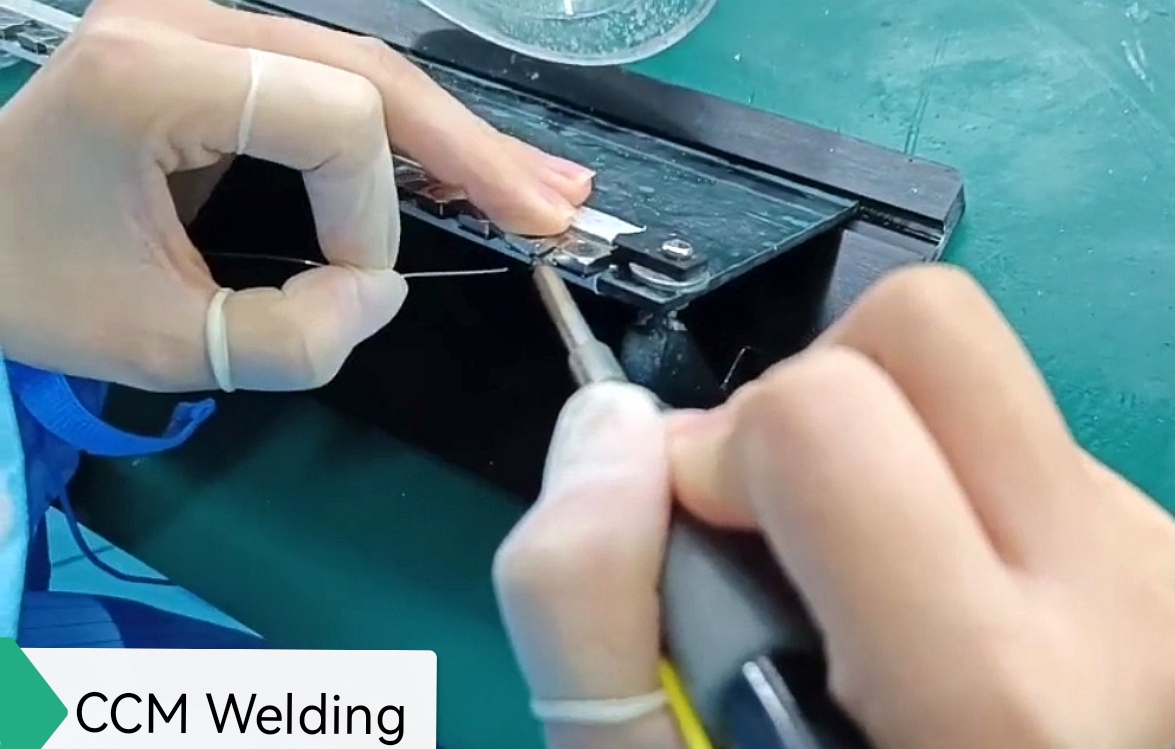

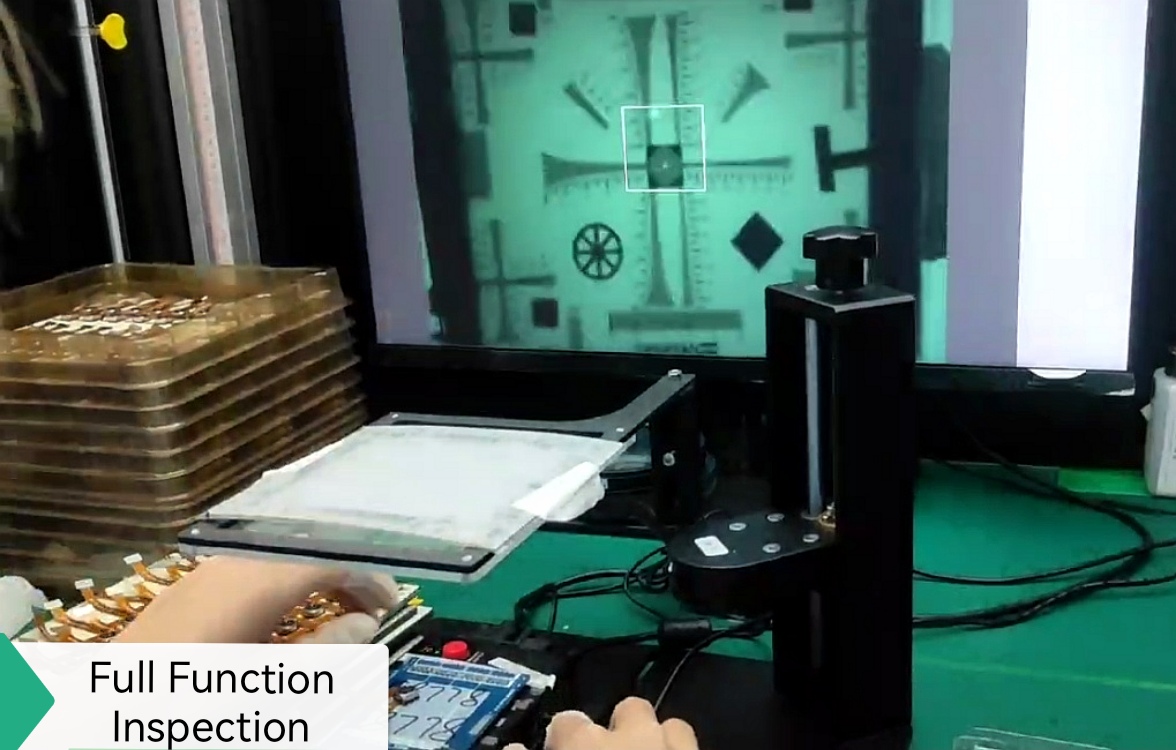

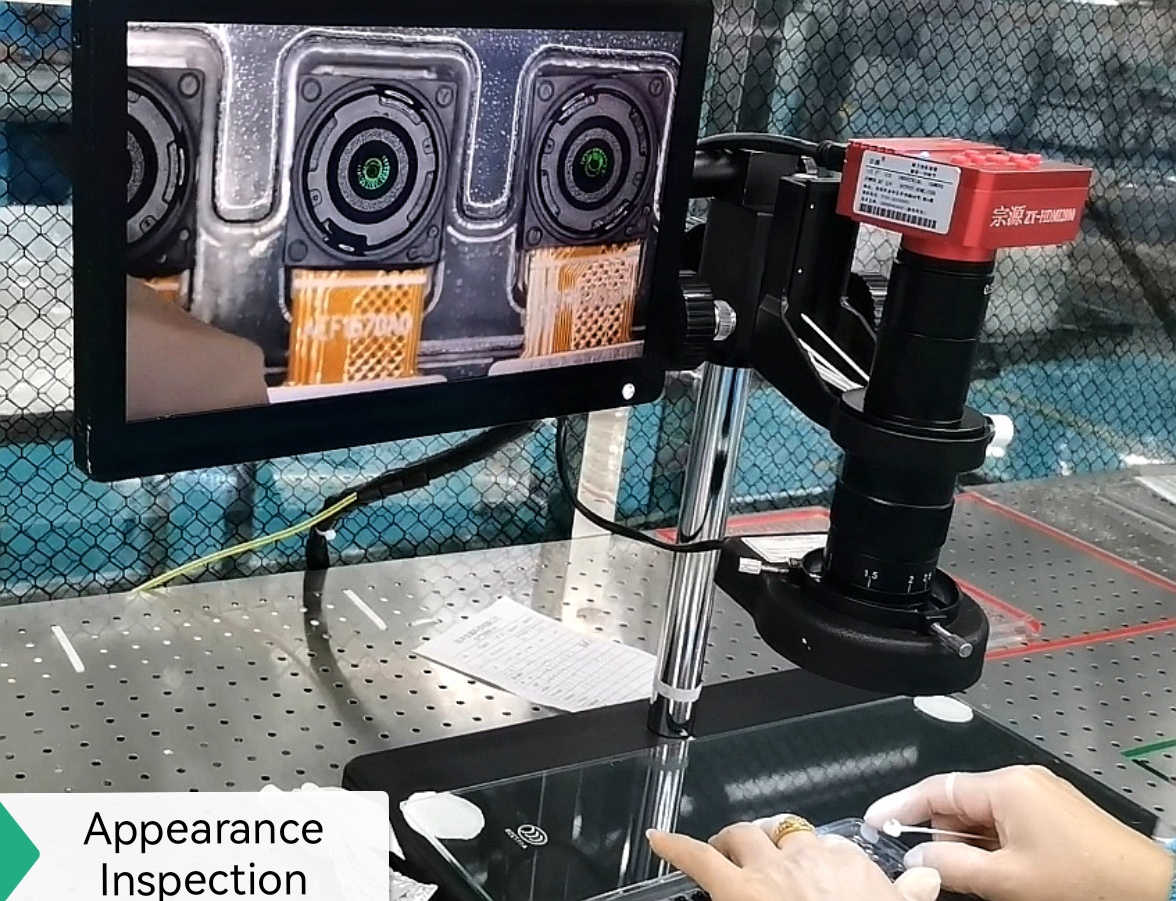

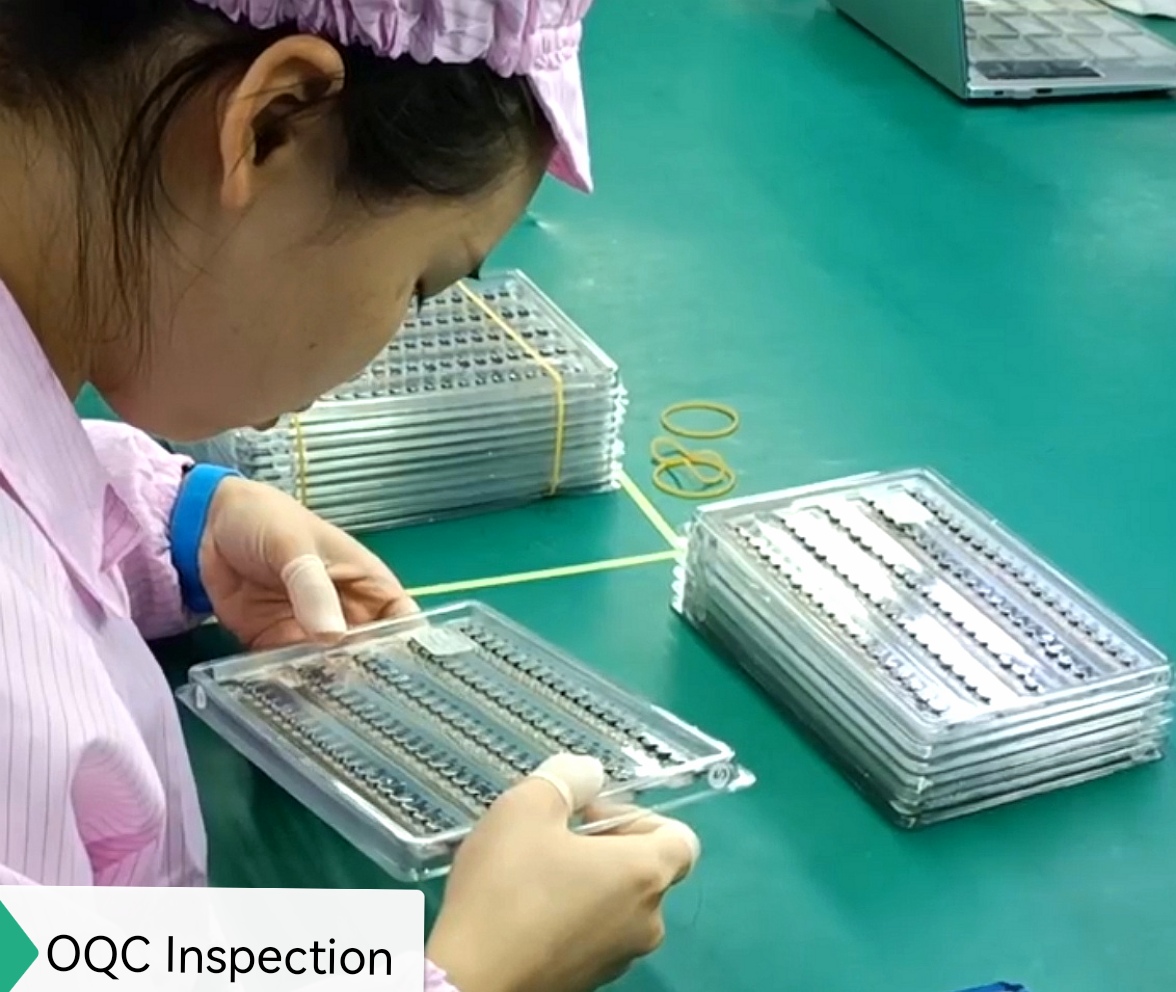

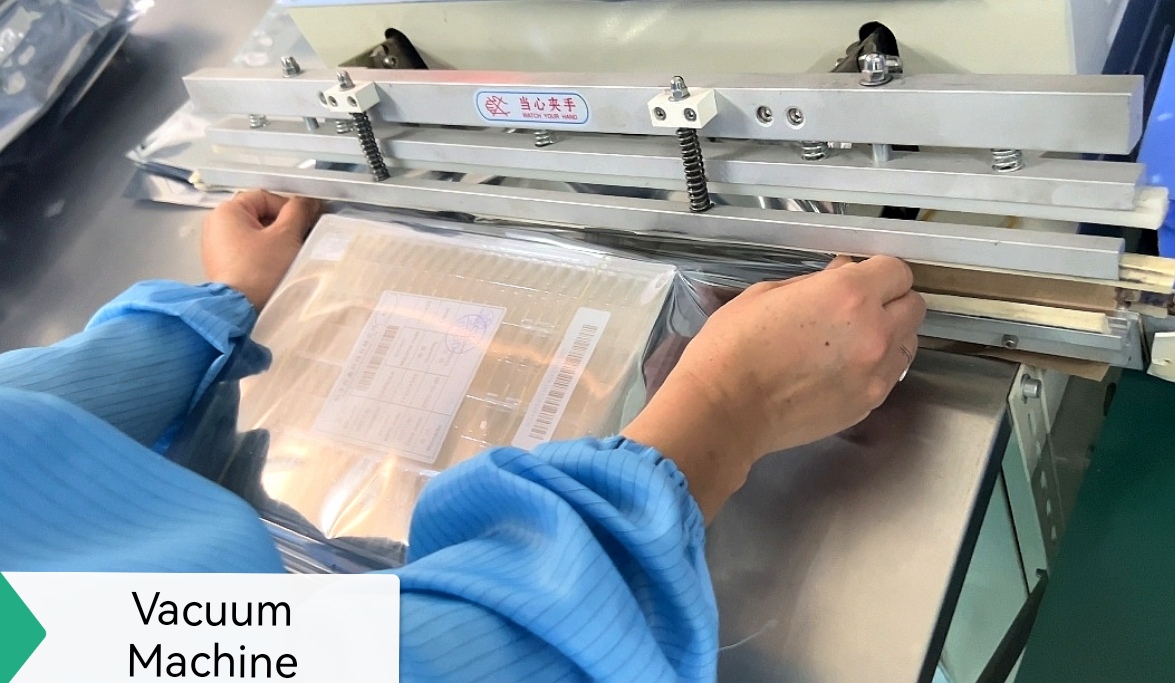

Vibration (simulating automobile transportation vibration table) - sub-board - focus - dispensing - UV glue inspection - UV curing - VCM welding - full function inspection —Appearance inspection-paste protective film—OQC appearance inspection——Vacuum machine

Contact Us Now

Want to sign a NDA, get a quote or just learn more about our camera modules? Get directly in touch with your local office contact!

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear